Prices incl. GST

Out of Stock.

- Product Code: Pololu-1093

- MPN: 1093

These tiny brushed DC gearmotors are intended for use at 6 V, though in general, these kinds of motors can run at voltages above and below this nominal voltage, so they should comfortably operate in the 3 – 9 V range (rotation can start at voltages as low as 0.5 V). Lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor. The micro metal gearmotors are available in a wide range of gear ratios—from 5:1 up to 1000:1—and offer a choice between three different motors: high-power (HP), medium-power (MP), and standard. With the exception of the 1000:1 gear ratio versions, all of the micro metal gearmotors have the same physical dimensions, so one version can be easily swapped for another if your design requirements change.

Details for item #1093

Exact gear ratio: 31×33×35×3416×14×13×14≈29.86:1

Gearmotor Dimensions

|

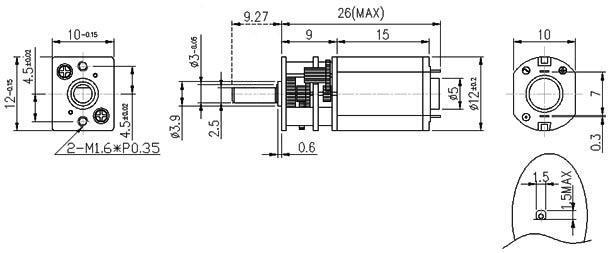

| Micro metal gearmotor dimensions (units in mm). |

|---|

The gearbox has a long (0.365" or 9.27 mm), 3 mm-diameter D-shaped metal output shaft, and the brass faceplate has two mounting holes threaded for M1.6 screws (1.6 mm diameter, 0.35 mm thread pitch). The gearmotor weighs approximately 0.35 oz (10 g). Versions with the extended motor shaft have a 1mm diameter round shaft that protrudes 4.5 mm from the rear of the motor, between the two motor terminals; this is not pictured in the above dimension diagram. In terms of size, these gearmotors are very similar to Sanyo’s popular 12 mm NA4S DC gearmotors, and gearmotors with this form factor are often referred to as N20 motors.

The gearbox on the 1000:1 and 1000:1 HP micro metal gearmotors is 12.5 mm long. All of the other micro metal gearmotors have 9mm-long gearboxes, as shown in the above dimension diagram.

Motor Accessories

- Wheels and hubs: The micro metal gearmotor’s output shaft matches our assortment of Pololu wheels and the Solarbotics RW2 rubber wheel. You can also use our Pololu universal mounting hubs to mount custom wheels and mechanism to the micro metal gearmotor’s output shaft.

|

|

|

|

| |